Quality

Steinhof's internal laboratory monitors the production process which has to be at the highest possible level. The core unit supervising the work and creating the necessary production elements is the laboratory (Research and Development Center).

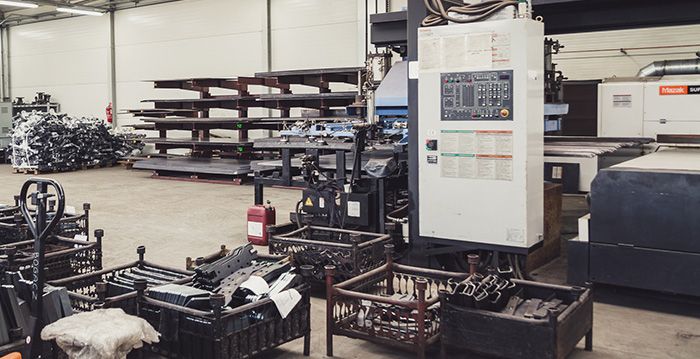

The basis of Steinhof's success is the high quality of all products, employees’ productivity and customer’s satisfaction. The safety is our priority, which is why every day highly qualified employees ensure that the production meets the strictest quality requirements. In our production process we use only components from reliable and certified suppliers. The whole production process is closely monitored at every stage. The supervision covers not only the suppliers of materials for production but also the whole manufacturing process, storage, up to the after-sales support.

Steinhof's internal Research and Development Center is responsible for the development, research and implementation of new technological solutions. At the same time, it performs the role of a laboratory cooperating with the quality control department and provides research facilities in the production of brake pads and towbars. The company's laboratory conducts basic physical and mechanical tests of friction materials both before they are put into production and when they are ready for use products.

Certifications

Steinhof’s products have the required certificates and approvals issued by the English unit – VCA (Vehicle Certification Agency) and also the Polish certificate issued by PIMOT (Automotive Industry Institute). By realizing the process approach to the production, the Steinhof company has implemented and effectively maintains the Quality Management System compliant with all requirements of ISO 9001: 2015. In addition, the GEM CERT certification agency is also responsible for the quality of Steinhof’s products.

Brake pads - process control

The control of the molding mixture/supply of the molding mixture consists of retrieving a representative sample, which is subjected to a series of tests to determine the quality, density of the friction material, the friction coefficient (ECE R90 Regulations), the wear of the material, its compressibility in hot and cold states (ISO standards), hardness (ISO standard) and the influence of high temperatures and humidity on the formation of a corrosive connection - brake pad - brake disc (ISO standard).

The bonding glue layer control relies on a random examination of the layers continuity and its thickness.

Pressing control consists of the measurement of the temperature of individual work items of the press (die, stamps) and its uniform distribution in the overall volume of the device.

The heating control bases on checking the temperature of the brake pads in the specified time – checking the temperature in the furnace using thermocouples and one-time temperature strips.

Finishing control checks the correctness of applying the powder paint layer (the destructive test), and also the correctness of the grinding process.

The friction materials test stands are equipped with specialized software that allows to perform various test cycles with high measurement accuracy. In the laboratory there are f.eg. an inertia stand that allows simulating the real vehicle braking conditions and a test stand for friction characteristics ( according to ECE R90) These devices allow the implementation of more and more perfect solutions, both in the composition of mixtures and in a complicated technological process. Each STEINHOF’S brake pad is marked by a permanent marking of the plate, which includes: the number and sign of the E-90 certificate, the batch code, the part number, the friction element code, the country identification code. The product packaging contains the name of the manufacturer of the brake pad, the certificate code, the name of the vehicle, which the approval was issued for, and the number of units. The packaging is also fully secured so that any derogation can be seen.

How do we test towbars?

Towbars are tested for compliance with the requirements of Regulation No 55 at the Automotive Industry Institute in Warsaw. Simultaneously, in the Steinhof's laboratory there is a modern fatigue-testing machine for towbars that has a valid calibration certificate issued by the Dutch Certification Institute RDW, which entitles the company to obtain e4 approval according to Directive 94/20 EC. Each towbar must be able to withstand 2 million cycles under the desired load, which takes about 40 hours. At regular intervals, the company undergoes relevant audits; so-called COP (Conformity of Production) carried out by RDW employees, which is to provide a constant and high, repeatable quality for series production of the towbars.